Additive manufacturing (also known as 3D printing) has been dropping in costs as the technology has been developing, which is resulting in more companies adopting the technology into their business. Unlike other manufacturing methods that excel at making products in bulk, 3D printing is great at producing products that do not need to be mass produced.

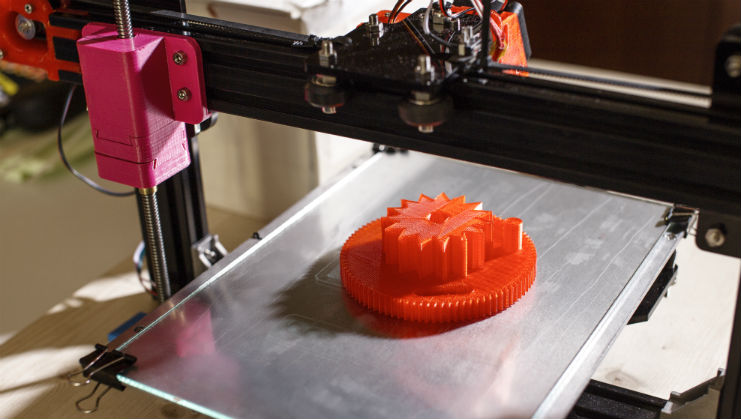

There are multiple 3D printing methods used, but the most commonly used is fused deposition modeling (FDM). FDM is a method of 3D printing were computer-aided design files are used to direct a mobile nozzle to distribute material, layer by layer until the product is complete. FDM usually uses thermal plastics and polymers or metals, but new developments allow the printing of concrete and even human tissue. Many industries are taking advantage of 3D printing and the trucking industry is no exception.

As stated by Truck Parts & Service magazine, many businesses in the trucking industry currently use 3D printing as a proof of concept for engineering purposes. This allows engineers to drastically cut time spent on testing new products or ideas; instead of needing to make a mold for each part or item they would like to test, they can 3D print it instead. While 3D printing is being used to assess the viability of newly designed parts or ideas, usage of printing in the trucking and supply chain industries has potential far beyond testing purposes. 3D printing could be used to create replacement parts for trucks or other heavy machinery.

Utilizing 3D printing to create aftermarket replacement parts increase cost-savings by keeping older equipment running longer, as parts become more difficult to source. Instead of needing to invest large amounts of cash to replace older equipment, new parts could be printed to keep the equipment running, regardless of the supply on the market. This allows supply chain and inventory management companies to potentially offer products that they do not currently have on hand. Inventory management businesses may even opt to not carry low demand parts that are easily printed as they could offer the product without needing to sacrifice any storage/warehouse space.

While additive manufacturing has a lot to offer to numerous industries, the technology has its own sets of issues and challenges. Will the printed replacement parts be of the same quality as their machined counterparts? 3D printing should be avoided for any truck or machinery parts that affect safety until research is done to understand whether they will retain the same integrity/quality as parts manufactured through other means. Air bubbles can result when 3d printing, often caused by incorrect printer calibration or humidity (which can affect the filament). Another current challenge faced by 3D printing is the printing speed. Although printing speed has increased greatly since the technology was invented, larger parts could take several hours to complete. Printing speed can be increased often at the expense of quality. Patents may also be an issue for businesses looking to make aftermarket replacement parts.

Additive manufacturing has the potential to extend heavy machinery’s life span by providing replacement parts that are no longer available. It can also offer customizable parts that are not otherwise available, such as custom nozzles or O-rings designed specifically to a company’s specifications. The limitless uses for 3D printing will push all industries to innovate, and the trucking and supply chain industries have a lot to gain from the technology.